Quality

At Metlex Extrusion, we prioritize quality above all else, and our dedication to excellence is evidenced by the certifications we have attained as a company. Our commitment lies in delivering high-quality products to our customers. To uphold this standard throughout our production process and ensure precision in our products, we remain diligent from the initial purchase of raw materials to the delivery of finished goods.

In-house Quality Check Equipment

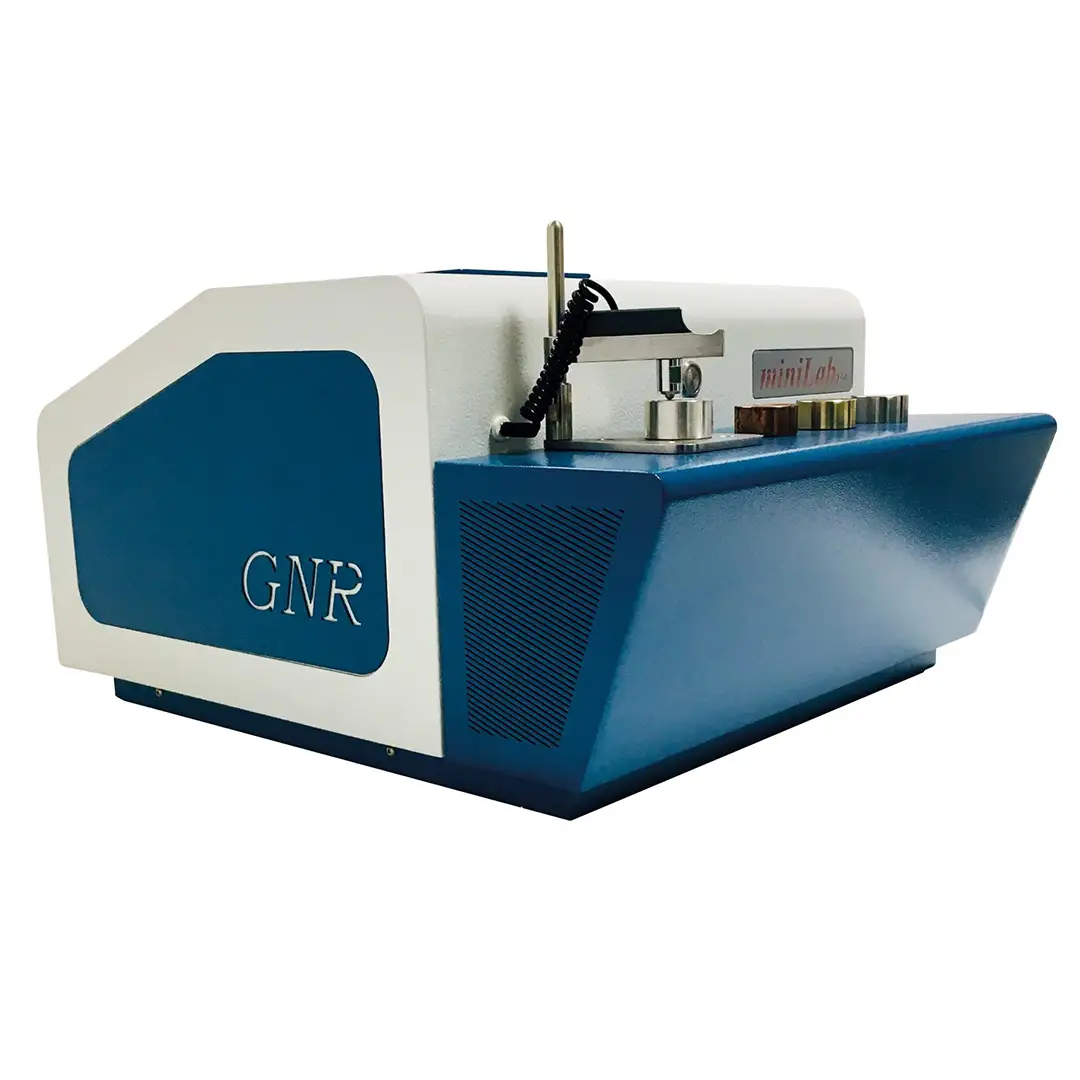

Metlex's Quality Assurance Laboratory is outfitted with state-of-the-art testing equipment to maintain the highest standards for our products. Recognizing that quality instruments are essential for ensuring product excellence, we have made significant investments in acquiring a wide range of inspection instruments. This includes general-purpose instruments and gauges, as well as specialized equipment like profile projectors and other sensitive instruments, to guarantee thorough and precise testing.

- Optical Emission Colour Spectrometer for controlling alloy chemical composition.

- Hardness and UTS machine for mechanical testing of profiles.

- Electrical Conductivity meter for testing of Electrical conductivity of profiles in % IACS.

- Profile projector for determining minute details of critical dimensions.

In addition to the specified equipment, our skilled workforce from the Quality Control Department maintains vigilant oversight of all plant processes. Continuous improvement of our products is ensured through ongoing Research and Development, guided by technical experts. We uphold meticulous organization and conduct process inspections at every stage to guarantee that our customers receive only the highest quality products.